Hall sensor renders PLS’s lifting systems reliable

These unique systems are used by both care homes and hospitals to provide support in the intensive care of patients. Sentech then proceeded to develop sensor solutions for the lifting unit’s rail system. Sentech and PLS are a good match, as both continually seek to make improvements in their pursuit of perfection.

The partnership has already led to development of a Hall sensor, which vouches for reliable control of the rail system. What’s more, Sentech is currently working on a new design for the handset.

The desire to continually improve calls for a development partner

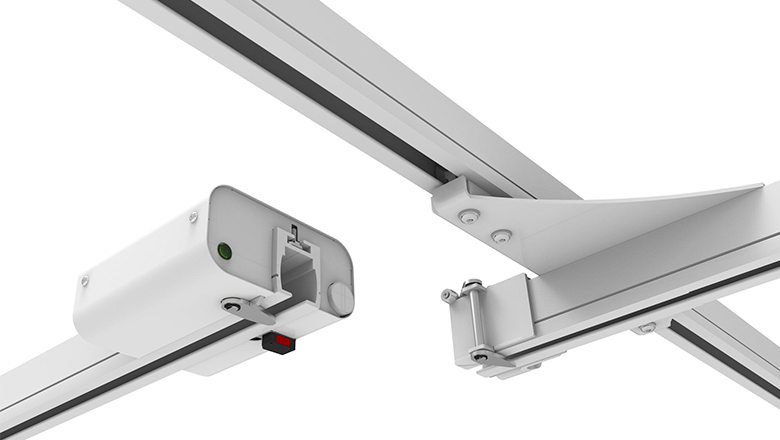

The rail and lifting system that PLS supplies to care homes is unique in terms of its ease of use, high level of automation and contactless operation. This makes it a low-maintenance unit, which is appealing to users. As a result, PLS systems are exported to various European countries, and as far afield as Australia and Asia.

PLS is constantly on the lookout for ways to achieve improvements. “I only envisage ongoing developments,” Mr. Van den Brandt says. “We ask our customers to provide feedback on error messages from the rail system. Thankfully, these are very few, averaging just 2 in 500 coupling operations. We are nevertheless keen to improve the product on the basis of these error messages. PLS supplies exclusivity in the upper market segment. That’s why I strive for perfection.”

Mr. Van den Brandt also pushes for perfection among his suppliers and development partners. Mr. Van den Brandt: “Our partners are also characterized by their endeavor for perfection and solution-oriented approach. While we may be an international firm, we like to source our development knowledge and components close to home. We firmly believe in short lines of communication and flexibility.”

All of the suppliers are therefore based within an hour’s drive from Renswoude. “And none considers it a problem to drop something off to us the same afternoon, if we call them that morning. You really need partners that can be relied on in a development process.”

And that’s why Sentech has proven such a suitable development partner to PLS.

Technical challenge: from mechanical to electronic

PLS approached Sentech with a clearly defined development request. Mr. Van den Brandt: “We were looking for a supplier that could provide a Hall sensor to replace two separate positioning sensors (reed switches). There was no standard sensor available, which could be ordered from a catalogue or suchlike.”

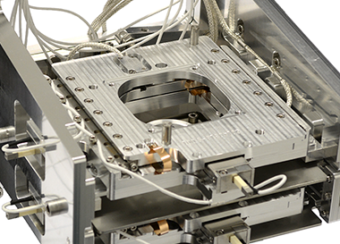

PLS supplies rails, couplings, points and roundabouts for the rail system. And everything within the system is controlled by sensors. PLS therefore wanted a generic sensor, as it was keen to replace the system’s mechanical components and reed-switch control with electronic ones.

“Electronic components and control systems are both more reliable and less susceptible to breakdowns than mechanical ones,” Mr. Van den Brandt explains.

Sentech developed a Hall sensor for the contactless control system, which was fitted in a custom-made housing. As the name suggests, this type of sensor operates on the basis of the Hall effect. The sensor measures the strength of a magnetic field, or rather the proximity of a magnet to the sensor.

A Hall sensor is highly suitable for contactless detection as it can measure the magnetic field straight through the cross-section of the lifting system. The sensor also enables the adjustment of the rail system according to particular requirements.

Sean Ram, Account Manager at Sentech, supervised development of the Hall sensor from the very outset. “Sentech is good at developing new sensor applications,” Mr. Ram enthuses. “We first assess the problem, then consider all the relevant factors and conditions, before proceeding to devise solutions. During the process, we endeavor to select suitable standard sensors to match the particular sensor tasks and circumstances in question.”

This is the quickest and most effective approach. “If it fails to yield an optimum solution, however, then we proceed to modify suitable sensors.”

The relatively short development project executed in this case revealed that a Hall sensor was the most suitable solution. Mr. Ram: “Sentech currently supplies the sensor and wiring only. The next step in the process will be to manufacture a complete assembly, which should render the entire system even more reliable.”

New developments in an ‘open kitchen’

Mr. Ram greatly appreciates the open attitude adopted by both PLS and Mr. Van den Brandt himself: “Sentech and PLS cooperate with one another in a kind of open kitchen. We share as much information as possible about our development processes, with a view to gaining the greatest benefit. I often pop over to Renswoude, to stroll around the workshop together with Marcel and spar with one another about progress and new developments. Given that it is all demand driven, we never quite know where we will end up.”

PLS approached Mr. Ram with another development request in the spring of 2016; one which initially appeared to have nothing to do with sensors. Mr. Van den Brandt: “We have been using standard handsets to operate the lift system for quite some time now. However, the design of this handset is not really ideal for our application. The cable is attached at the base, for instance, while it should ideally be attached at the top, to provide additional comfort and convenience. What’s more, the handset is not splash proof.”

In short, PLS was looking for a new unit with a more exclusive image. “Our current supplier cannot provide such an item, unfortunately. During the course of a general conversation, I happened to mention our need for a new handset to Sean, who pleasantly surprised me by expressing an interest in producing one.”

Mr. Van den Brand hit the nail on the head with this anecdote. Sentech is a sensor integrator, developing complete sensor assemblies by combining sensors, wiring, housings and connectors. Mr. Ram explains his response to PLS: “My initial thought was that it was not actually a project that would involve sensor technology. On considering the matter at length, however, I came to the conclusion that producing a handset was entirely in keeping with Sentech’s competences. I therefore passed the request on to our engineers straight away. R&D also involves a great deal of creativity.”

The engineers did not think twice therefore about accepting the challenge. They came up with a customized, integrated technical design, including an injection-molding model designed to lend the new housing an exclusive appearance. Mr. Ram: “We hope to be able to proceed from development to production sometime next year.”

Are your unique systems ready for improvement? Present our challengers your challenge!