Vacuum sensor solution in a unique microscope

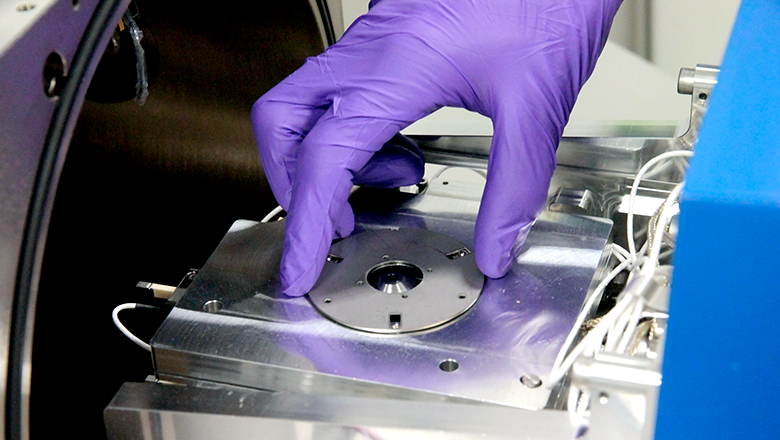

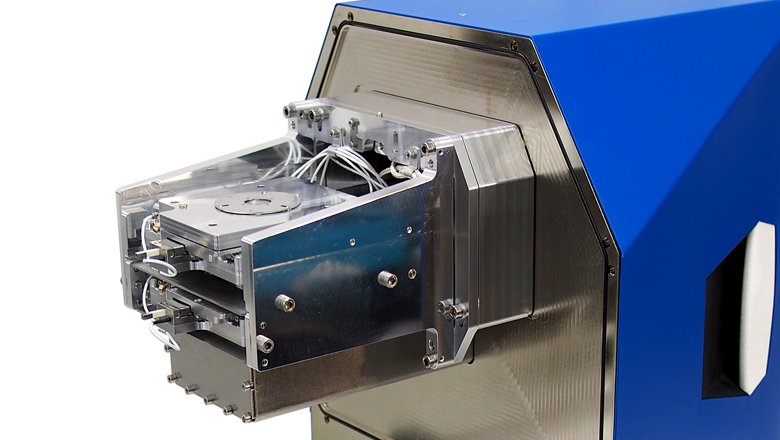

Delmic SECOM 2.0 has conquered the international microscopy world with Sentech’s vacuum sensor solution. This is the only device in the world that combines fluorescence and electron microscopy in a single integrated setup. The unique microscope is compatible with all types of SEM electron microscopes.

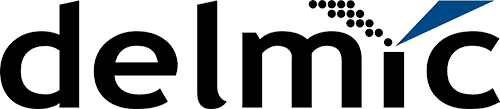

Sentech has developed a vacuum resistant optical encoder solution for positioning the sample in the vacuum space. The independent sensor integrator provides the solution as a sensor assembly, enabling Delmic to assemble it easily in SECOM 2.0.

Combination of fluorescence and electron microscopy

Delmic employs a workforce of 13 people to develop and produce high-quality microscopy technology. Its product range offers SPARC solutions for material research and SECOM solutions for biomedical research.

“Delmic combines fluorescence and electron microscopy in the SECOM system,” Andries Effting, CTO and co-founder of Delmic begins. The correlative light and electron microscope (CLEM) can be integrated as a module in almost every scanning electron microscope (SEM), also known as a grid electron microscope.

The technical physicist and his partner Sander den Hoedt continue to build on research by the Delft University of Technology (TU Delft) and AMOLF. In 2011, this research resulted in the SECOM 1.0 prototype.

“We needed around two years to bring a suitable microscope to market from the prototype. SECOM 2.0 differs markedly from the prototype, but the concept has remained the same,” says Effting.

Scientists carry out ground-breaking biomedical research using high-tech microscopy technology contained in the Delmic system.

Fluorescence microscopy

Fluorescence microscopy, invented in the 1970s, is an optical method used to investigate cell function. Researchers add chemical markers to a sample that bind to specific proteins.

In the image produced by the microscope, the marked proteins are illuminated in various colours. Proteins facilitate all the different processes in living cells. Using fluorescence microscopy, scientists acquire a picture of processes that lead to disease.

Electron microscopy – TEM and SEM

An electron microscope shoots a bundle of electrons at the sample under examination. Accelerated electrons have a much smaller wavelength than photons (light), producing a resolution of a factor of 2000 higher than an optical microscope.

A transmission electron microscope (TEM) shoots an electron beam through the sample, producing a slide projection of sorts. The method can produce magnifications of up to a million times: 0.1 nanometre.

A grid electron microscope or scanning electron microscope (SEM) bundles the electrons in the direction of the material and captures the reflected electrons in an image point by point. SEM produces magnifications of up to 100,000 times as well as very sharp 3D images.

Benefits of CLEM for medical science

According to Effting, Delmic’s CLEM offers a number of benefits over individual systems:

- Ease of use

The researcher no longer needs to produce two images from separate devices and then unify them using software. - New research opportunities

Short-life samples can be examined. It only takes a minute to produce an image of a sample in practice. - Technical image quality

The images offer incredible levels of detail, which are not possible using other devices. - Time savings

In cases where research time is limited, the system saves a huge amount of time. The short machine time, for example, makes it possible to carry out population research quickly.

Benefits in a nutshell: open source software

Effting jokingly calls his company “a photography company”. This explains Delmic’s choice to offer customers open source image processing software. “The software just has to be good,” he says.

“Excellent software provides a better product experience. We see our software as the business card of the instrument. Competitors leave gaps in this respect. If our customers discover a mistake or problem, we simply fix it. They don’t have to wait for releases and updates, and don’t have to pay licence fees, although they do pay for the support we provide. Open source offers users transparency. The code is available online,” the CTO explains.

Integration in almost all SEM types

We deliver the optical microscope and software,” explains Effting. “There are plenty of companies that deliver excellent SEMs. Our system fits the SEMs of the five major suppliers: ZEISS, Tescan, Hitachi, Fei and JEOL.”

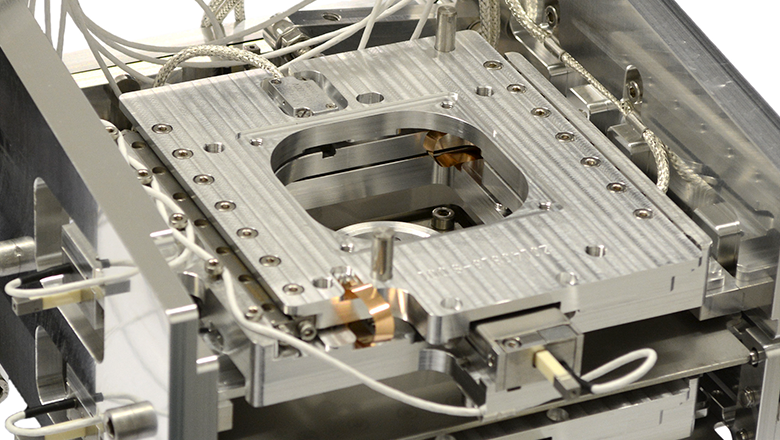

The SECOM stage replaces the SEM stage. Effting continues: “We’ve developed microscope-specific interfaces for this purpose. We’ve optimised the software for each SEM type. Our customers can choose SECOM as an option from the SEM supplier or directly from Delmic.”

Breakthrough bio-scientific research

Delmic’s CLEM microscopes are now finding their way into labs at various universities and research institutes worldwide.

Dr. Ben Giepmans applies the microscope to diabetes research conducted by his cell biological research group at the University of Groningen. He and his scientists focus on the Islets of Langerhans in the pancreas. They are, for example, investigating triggers and new treatment methods for type 1 diabetes.

Headed up by microbiologist Lucy Collinson, the Francis Crick Institute applies SECOM for cancer research, amongst other things.

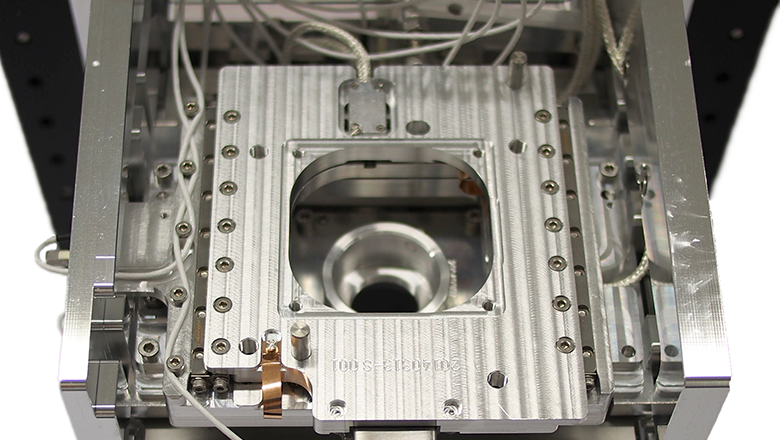

Vacuum sensor development for the vacuum space

SECOM 2.0 owes its extreme accuracy and high resolution to a unique optical vacuum sensor. Sentech delivers the customised MicroE optical sensors in a fully tested and calibrated assembly.

Delmic receives three sensor assemblies for each CLEM system, one for each axis of motion, which can be assembled quickly and easily.

Encoder sensor MicroE for accurate positioning

Delmic was looking for a reliable sensor solution to accurately position the sample in the vacuum chamber. Sentech came into the spotlight at Delmic after a search via Google.

This led to a joint search for a suitable sensor solution based on the accuracy requirements and circumstances of the stage.

Peter Verstappen, account manager at Sentech, explains the development process: “The challenges were the accuracy, vacuum conditions and limited installation volume. This involves nanometres and an extremely precise focal point of the optical microscope.”

Accurate position sensor – material use and low energy consumption

The vacuum reduced the position sensor’s search spectrum in terms of material use and energy consumption. The outgassing of a variety of materials including plastics takes place in the vacuum, contaminating the sample and the surroundings.

Another problem is the lack of air-cooling options. A sensor that generates as little heat as possible was therefore needed.

“We’ve passed the entire MicroE line with position sensors as well as a number of competitors. Because of the specifications, 90% fell off immediately,” says Verstappen. Effting responds: “We were therefore quick to agree on the application of a MicroE optical encoder. It was great to be able to talk about our requirements and specifications in an easy way.”

Optical encoder operation

The optical sensors determine their position on the axis of motion using a reading head and a very fine ruler, upon which a pattern of stripes is placed with a period of 20µm.

The linear optical encoder does not contain LED as a light source, but a VCSEL-controlled element that requires far less energy. The absence of a lens also contributes to the compact position sensor.

“We’ve adapted the ruler to the accuracy requirements,” says Verstappen. The light source shines on a pattern of reflective and non-reflecting stripes, creating ‘nodes’ in the reflection pattern.

These are coinciding crests and troughs of the specific wavelength and are captured by the sensor receiver. This is comparable to the principle of light passing through a grille network. As such, a movement can be made visible in one movement for each period.

Incremental measurement system with interpolation

The incremental measuring system converts the movement into counts. The movement is accurately controlled in relation to a fixed unique point on the ruler: the index.

Verstappen about accuracy: “The sensor interpolates the intrinsic period from 20 micrometres to steps of 1.2 nanometres, or a multiple thereof. We needed the highest degree of accuracy for the z-movement.”

He continues: “Due to cost and handling considerations, we decided to use the optical nano-sensor for each axis.”

High-quality materials in optical sensor assembly

In addition to the specific sensor, Sentech and Delmic paid a great deal of attention to the quality of the other components. Effting wanted to avoid discussions with various suppliers about sensor components.

“We offer a high-tech system. So you don’t have to scrimp on the costs with cheap connectors and cabling, for example. You don’t want to be confronted with liability conflicts afterwards.”

Semiconductor industry experience

Sentech took advantage of his experience in the semiconductor industry. “That’s why we chose for the standards and high quality of the semiconductor industry and advised Delmic not to screw joints but to solder them,” explains Verstappen.

The semiconductor experience also led to the logical choice to produce and package the sensor assembly in Sentech’s cleanroom.

“In so doing, Sentech makes it so easy for us, because we’re certain the entire sensor application has been tested. At our assembly facility, we only have to take the sensors out of the packaging, after which we can assemble them immediately and quickly,” says the satisfied Delmic founder.

Conquering the world with reliable sensors

According to Effting, satisfaction with Sentech stems not only from pleasant cooperation in an open development environment. “SECOM 2.0 has been on the market since 2013. To date, all of the sensors have been working flawlessly. The specifications and performance levels promised at the outset have been fulfilled.”

The SECOM platform has proven its worth, and is slowly but surely conquering the microscopy world.

Your outcome too?

For the reliable positioning of a sample in a vacuum room, a vacuum resistant optical encoder presented the solution for Delmic. Are you also looking for a reliable sensor solution for your positioning and control issues?

Present us with your challenge and we will help you!