Pressure sensors: measuring pressures

Liquids may also cause the water hammer action: an ultra-short pressure pulse that arises when a tap is suddenly closed. Most sensors are not able to cope with this. Always be sure to check the peak pressures expected in your system and what a sensor can handle.

Measuring pressure with piezoelectric sensors

Pressure can be measured in various ways. The most common pressure sensors contain piezo element, a crystal wafer that deforms under pressure. This deformation generates a voltage that can be accurately measured. The thinner the wafer, the more sensitive it is to lower pressures. This type of sensor is popular because it is easy to produce and relatively inexpensive.

It is also fast, and can detect minor changes in pressure. The downside is sensitivity. If the pressure rises too high, these kinds of sensors can break. For example, the water hammer effect can literally punch a hole in the wafer. This is completely unacceptable when working with harmful or flammable media.

One solution is to immerse the piezo element in oil and seal everything with a membrane. This layer provides protection and makes sensors like these more resistant to high pressures. However, if the pressure rises too much, the membrane will bend or tear. This type of sensor can be used in the food industry, but only with special food-grade oil.

Measuring pressure with capacitive sensors

The second group of pressure sensors uses capacitors to measure pressure. The applied pressure reduces the distance between two capacitor plates, which changes the capacity of the system. This method is very robust, and can handle very high pressures. The downside is that these kinds of sensors are slightly more expensive than the piezo equivalent. They are also much larger, sometimes even 25 times as large.

Measuring pressure with strain gauges

The third option is to use strain gauge pressure sensors. Like a load cell, these sensors consist of a piece of metal with a deformable strip: a piece of resistive foil with a carbon pattern. The resistance changes according to how this pattern deforms under pressure. An electronic circuit called a Wheatstone bridge can accurately measure the change in resistance. These strain gauges are incredibly durable but also very expensive, because they are often handmade.

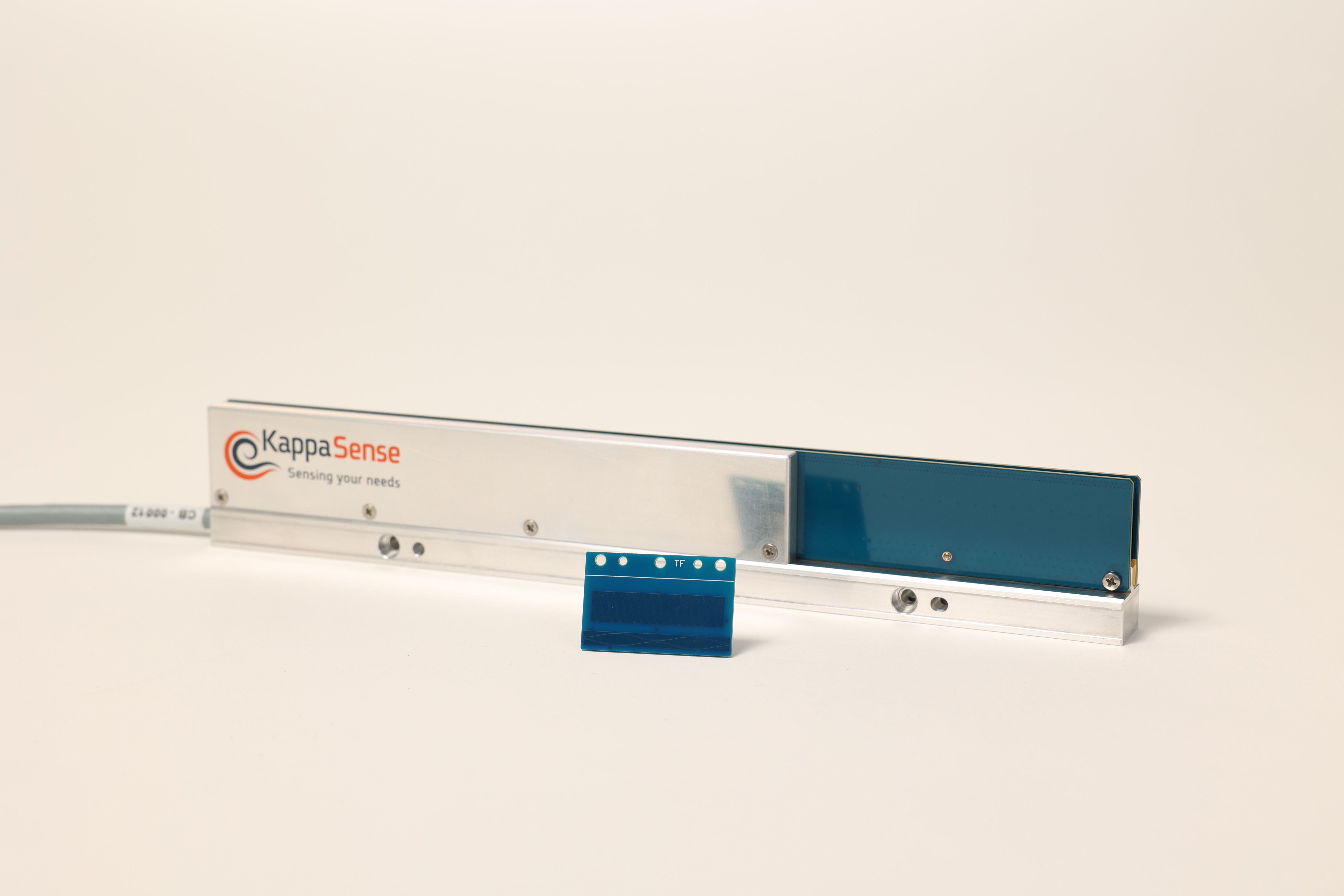

Featured pressure sensors

Need some help?

Our brand-independent sensor database only lists a selection of the sensors available. There are so many different technologies and manufacturers that our online sensor database can never be 100% complete. If you can’t find what you’re looking for, or you have a question, send an e-mail to our sensor experts. We’ll gladly help you with your search.