Pulsotronic: inductive sensors for contaminated environments

Think custom-made sensors are only for large orders? Nonsense! Together with Pulsotronic, we make modified inductive sensors accessible in small quantities, as well. Such as sensors for position detection used in harsh environments. What do you want to measure, and which technology do you need to do that? And how do you integrate this sensor? With Sentech’s support, you compile the right knowledge of technology, production, integration and application. That’s how you integrate a reliable sensor solution.

How do you integrate inductive sensors?

For the integration of inductive sensors, we use the technologies and capacities offered by Pulsotronic. They don’t provide just any old customized sensors. It’s all about the physical quantity that you want to convert to a signal. Together with our partner, we select the technology that offers the very best way to do this.

Here, Pulsotronic has the technological and production expertise in house and Sentech knows all about integration and application. If small volumes are needed, Sentech creates the complex sensor solutions. But as soon as the volumes become larger than, say, 50,000 units, it is more efficient for Pulsotronic to do the assembly. In doing so, Pulsotronic is like an extension of Sentech.

Valuable facilities for reliable sensor solutions

Our partner is incredibly quick at creating prototypes, and they are not dependent upon other organizations to do this. Pulsotronic makes jigs, does die-casting, and has test capacity in their own test laboratory for EMC certification and climate testing. On top of all that, they also have their own electronics assembly department. Pulsotronic has it all in house.

For the creation of a housing, they also have the right knowledge and experience, such as in ultrasonic welding. This technology is used to weld various plastics together. The result is an invisible and stronger joint than what can be achieved with gluing and melting. Pulsotronic also has a command of various technologies for potting.

And service is more than just developing a sensor solution. If a sensor does not function (or function well), Pulsotronic tracks down the cause using an X-ray scan. After all, they have their own X-ray machine.

Position detection in harsh environments

presence of all types of metals. This type of sensor is insensitive to dirt such as dust, moisture and oil. This technology is contact-free, which also makes the sensor resistant to wear.

These properties also make inductive technology suitable for applications in harsh environments, such as those found in mechanical engineering, but also for agricultural and automotive applications

-

Position detection in mechanical engineering and automotive

Its sensitivity to metal makes inductive technology extremely suitable for the detection of moving metal components. You see these sensors used on lifting cranes to detect cylinders and steel cables, among other uses. -

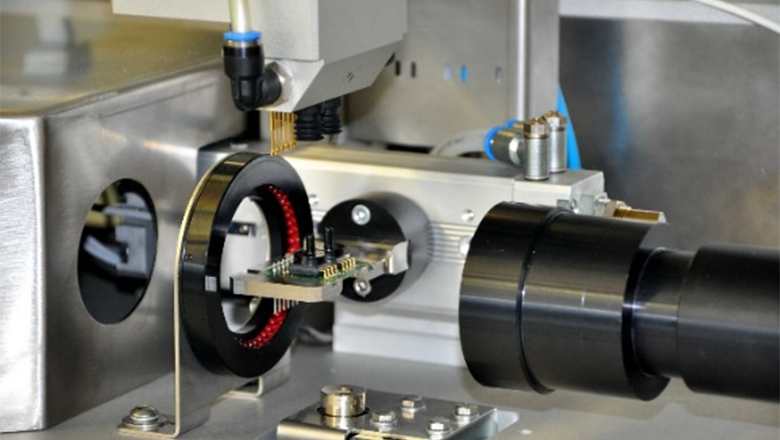

Angular rotation sensor

Inductive technology is also the solution when you need to measure angles. Such a contact-free angular rotation sensor is a good fit for automotive solutions, for example. The contact-free sensor is both wearproof and waterproof.It is possible to implement this solution with redundancy. In other words: two circuits in the sensor work independently of each other. The advantage here is that the sensor will continue to function even if one circuit fails. This solution can also be provided with an ECE quality mark. Along with an E-marking, an ECE quality mark is required within the European Union for electronic components in vehicles. These quality marks assure, for example, that the sensor is not influenced by external radiation.

Who is Pulsotronic?

Pulsotronic develops and produces sensor technology and electrical components for machinery, automation, and the automotive sector. As a subsidiary of the German company Phoenix Contact, it operates worldwide.

In addition to its range of inductive sensors, Pulsotronic provides technologies such as those for the development of angular rotation sensors, force sensors, magnetic hall sensors, and optical sensors. Together with Pulsotronic, Sentech develops solutions that go beyond existing technologies. A few examples of where you can find these sensor solutions are in various agricultural applications in large OEMs.

How do you select the right sensor?

To arrive at the most suitable sensor technology, you must first know what you really need. How do you select the right technology? And which criteria should you collect?

Our 10 questions will help you do this.