Omron in the Netherlands: light sensors for measuring distance and thickness

Omron has many laser and light sensors for measuring distance, among other uses. Which ones do you need? Your specific engineering project requires reliable knowledge from a sensor expert. It necessitates far-reaching knowledge about the selected product and the technology used. Omron works with Sentech to deliver customer-specific sensor solutions. How can this help you, as an (R&D) Engineer? Read on to find out.

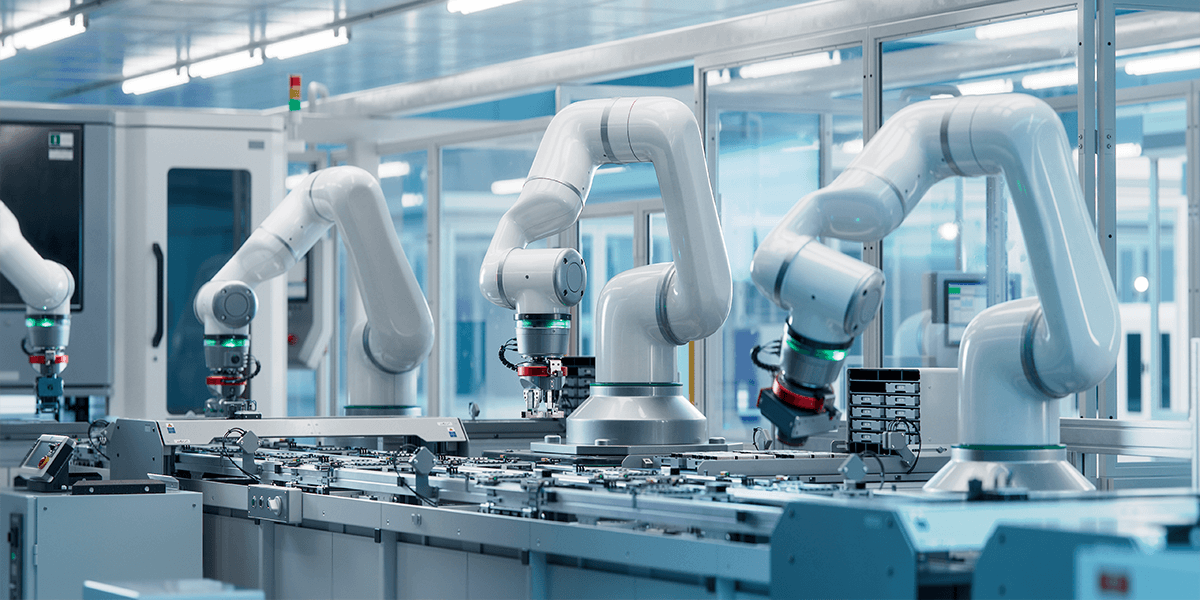

Omron sensors are produced in large numbers, so if you’re looking for standard mass-produced products, you’ve come to the right place. The need for smaller, specific batches of adjusted light sensors, laser sensors and other measurement sensors, however, is fulfilled by Sentech. This requires far-reaching specialist application knowledge in the high-tech and semiconductor markets.

More than 10 years of collaboration on measurement sensors

“We adjust sensors from Omron with the right plug and cable, or we mount a sensor on a bracket and program the sensors for your environmental situation,” says Sean Ram, Account Manager at Sentech. “We have been making customer-specific assemblies in close collaboration for more than 10 years now.”

The laser technologies of Omron can be adjusted at multiple locations and in many different types of machines for the high-tech sector and semiconductor industry. Besides the complete adjustment of assemblies, Sentech also produces the right cables, connectors and mechanical interfaces.

Ram explains: “We share the experience we have gained with measurement sensors, such as laser triangulation, with you in your sensor project.” What’s more, special fiberglass models and amplifiers can also be suitable for your application.

Much-used Omron sensor

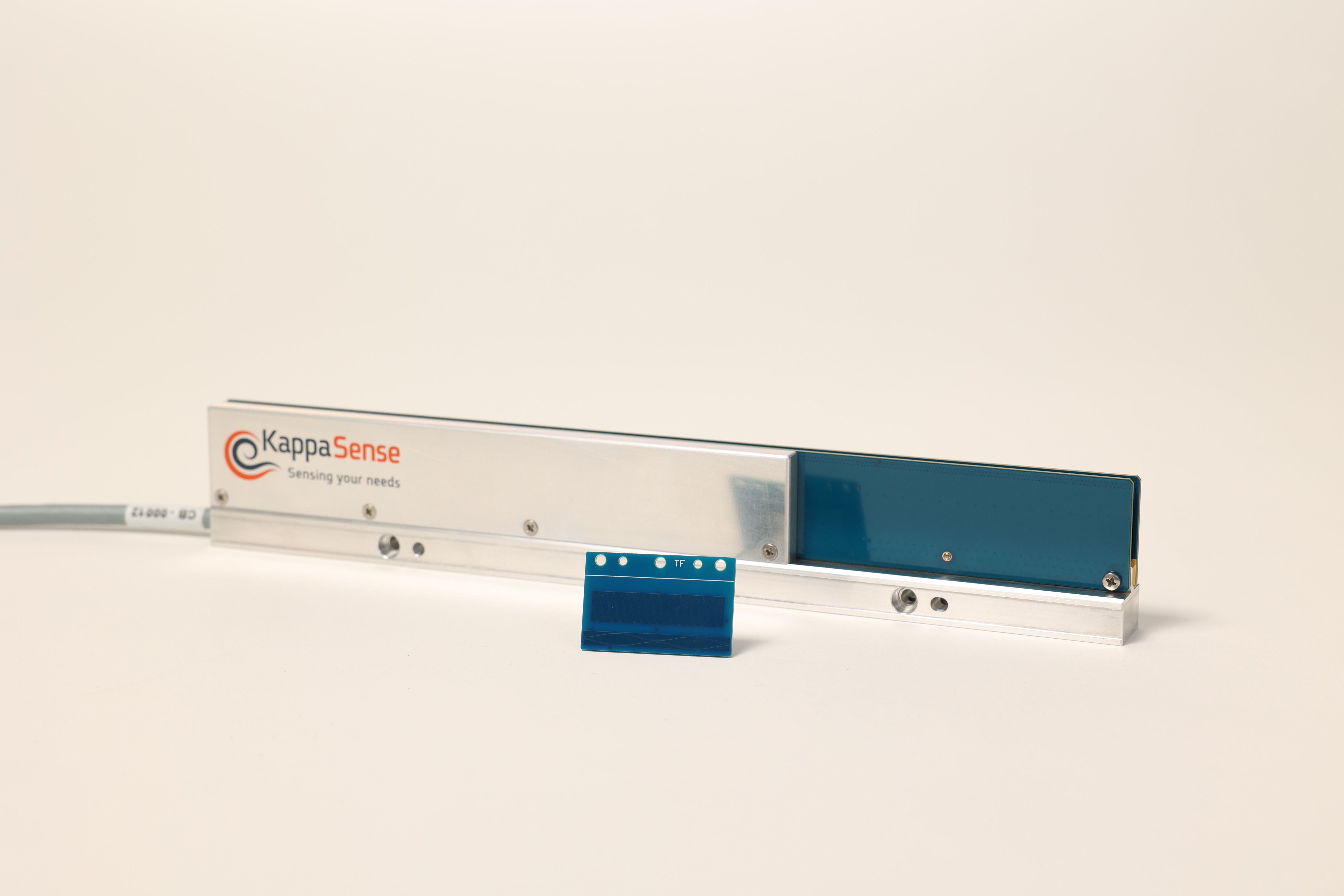

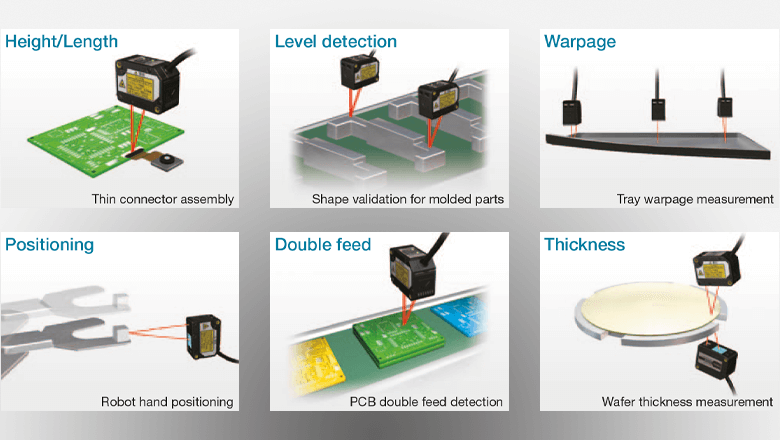

With laser triangulation, you measure distance and thickness in high resolution. Three common measurement sensors that engineers use – after adjustments – in their projects are the ZX1, ZX2 and ZX-L sensors from Omron.

-

ZX1 (2D CMOS Laser triangulation)

This sensor uses an advanced HSDR-CMOS (High Speed and Dynamic Range) camera chip. Are you looking for the stable and highly accurate contact-free measurement of objects, even on variable surfaces, with a large range of measurement? With your sensor expert, check out whether this measurement sensor is suitable for your project. -

ZX2 (2D CMOS Laser triangulation)

High accuracy (1.5 – 5 µm) and speed (30 µs) are characteristics of measuring linear movements. The ZX2 has a HSDR-CMOS image sensor for achieving high measuring stability and it can also be adjusted with just one button. -

ZX-L (PSD laser triangulation)

Does your application require through-beam measurement with a high resolution and quick response time (150 µs)? Or do you want to determine the thickness of a material? Laser measuring systems are very versatile in use and suitable for many applications. Because the amplifiers can be interconnected, it is possible to perform multiple-point measurement using a maximum of five sensors.

Who is Omron?

Founded in 1933 and originally a Japanese company, Omron is one of the largest automation companies in the world. It is good at producing large quantities of standard sensors. Partly for this reason, Omron opts to partner with Sentech to serve the market for customer-specific sensors solutions.

“A company is most valuable if it contributes to society and doesn’t just pursue profits,” said Omron founder Kazuma Tateishi. As Omron Netherlands states, “We aim to create a society in which everyone can live more comfortably.”

In Europe, the company has been representing three divisions – Industrial Automation, Electronic Components, and Healthcare – for more than 30 years. Together with Sentech, Omron mainly works in the business of technologically advanced industrial automation products.

Key development goals in sensor technology

For you, as (R&D) Engineer, a successful implementation of new sensor technologies can be a real challenge. You face challenges and issues at the component level that you need help resolving.

Our article with 21 technological trends discusses the future of smart sensors, sensor data fusion and key development goals, among other trends.