Optimize your machine with big data sensors

Mechanical engineers and OEMs optimize machines by intelligently using big data sensors. End customer requirements and production methods have changed because of the industrial revolution. Flexible production lines, optimal yield, and maintenance friendly machines are the order of the day. You always need sensor data when you want to improve machines.

As an (R&D) Engineer, you want to make your machines more intelligent, often based on customer requirements. You know sensor technologies and their associated possibilities. But, how do you use sensor data to improve efficiency? Whether your machine optimization will be successful depends on collecting the right data and the use thereof.

Big data sensors are indispensable for machine optimization

Machines are loaded with technologies, such as sensors, that collect a lot of data about the machine. You will always need data regardless of what you want to improve in your machine. “The main outcome is accomplished by automated actions. If you measure all of these actions, you can examine what can be done faster and better for each subject. You can also research which processes can be run synchronously,” said Marco Leeggangers, Sentech Sales Director.

Machines will work more efficiently when downtime is reduced and processes are faster. “You can predict failures by identifying how often a specific motor or machine component fails. You can then improve processes based on this data. The end customer can recover their investment more quickly when the machine failures are at a minimum and processes are efficient,” said the Sales Director.

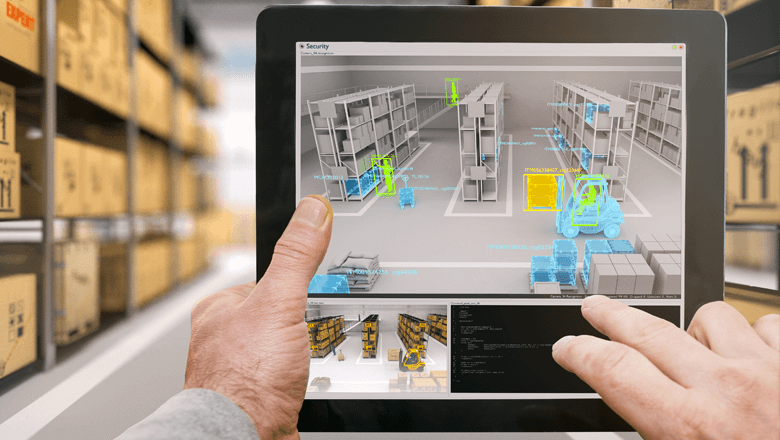

Big data also makes autonomous driving increasingly safe. Leeggangers explained: “By collecting data, we can recognize patterns that allow us to learn a lot about improving our machines. For example, we equip self-driving vehicles with technologies such as lidar, radar, ultrasonic sensors, and cameras. The combination of these four technologies provides valuable information. It allows an Automated Guided Vehicle (AGV) to distinguish between a person or other vehicle and a stationary or moving vehicle.”

Responding to the market need

To continue satisfying the end customer’s requirements, you must take a future perspective. A nice example is AGVs. These autonomous vehicles now drive on enclosed terrains. Despite self-driving vehicles just being introduced, we – the consumer – already have a picture of the future. And this picture is also influenced by what we have seen in science fiction movies.

Leeggangers shares his vision: “Eventually, we will drive vehicles completely autonomously in the future. We will not need a driving license to do so and you won’t even have to own a car. You will simply get in a car that is available in your direct vicinity.” This vision is far in the future. But, step by step, we are getting closer to that vision.

The influence of technological developments

Technologies continue to become more intelligent as the years pass. The sensors used today are not necessarily the sensors of tomorrow. We need to allow for other developments that can influence your product.

Leeggangers said: “In ten years or so, we may no longer use phones, but have a sub-dermal tag with GPS. If you then sit in a self-driving car, the tags will use multilateration (MLAT) to position itself and follow vehicles. The outcome is that we would no longer need sensors in the car.”

How do you collect data?

Data and making your machines more intelligent goes hand in hand with each other. Sensors in machines collect enormous amounts of data. In addition to big data from a machine, you can also combine that sensor data with data from other machines.

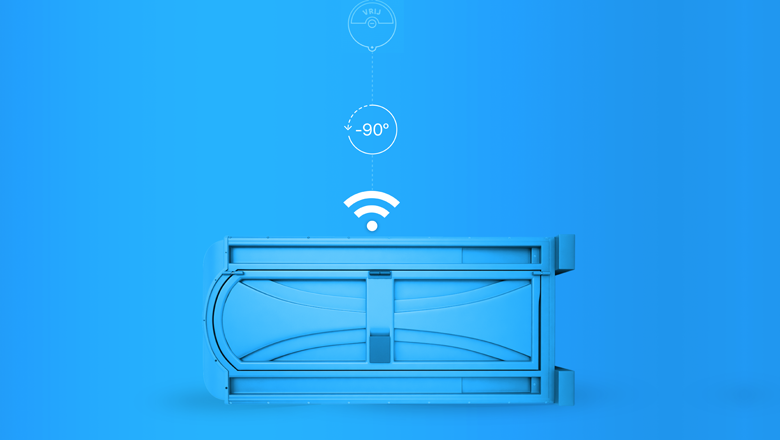

Internet of Things

You can make your machine even more intelligent with unidentified data. If you share your sensor data with others via the internet, information from others will also be available to you. The Sales Director shared his vision about sharing big data via IoT: “You can accrue significant new insights when you combine your datasets with those of others. You cannot foresee what you will be able to learn from it.”

End-user data

End-user machines collect a lot of data. This information is valuable in helping you improve your own machine. But, the end user is the owner of their data. So, how do you deal with that?

“For example, you see this with mechanical engineers who make dairy machinery. Milking robots collect huge amounts of data, for instance, on milk quality. The farmer owns this data. On the one hand, the farmer wants more intelligent machines to improve his yield. On the other hand, the farmer does not want others to get his data,” said the Sales Director.

Some functionality is only possible when the end customer shares their sensor data with you. For example, predictive maintenance. How do you prepare your end customer to share their big data?

Privacy legislation

The strict privacy act GDPR may create a challenge when collecting data. If you collect data with personal characteristics, you are required to inform those people using a privacy statement about the goal of the data collection. It must also indicate what data you use and the other organizations that you share the data with. Moreover, you must save the information in a secure manner.

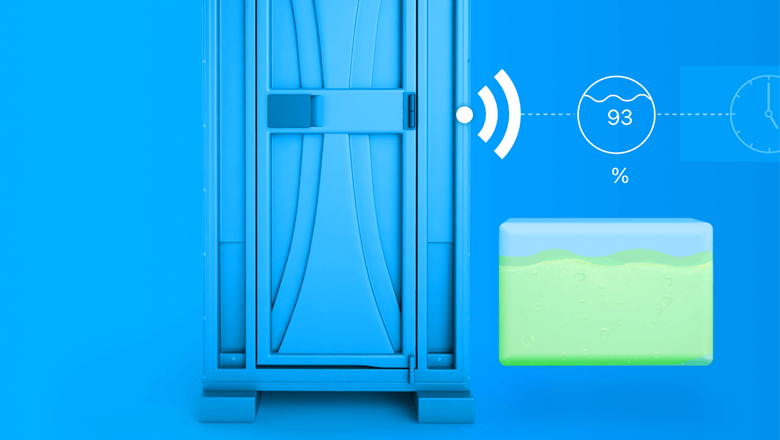

The integration of sensors in a mobile toilet and interfacing sensor data with a cloud platform gave rise to our IoT Toilet.

How do you make data usable?

If you collect a lot of data, you can analyze the data to recognize patterns. These algorithms look for a specific event, which you can associate with actions.

You do not need different big data sensors for every measurement. You can also combine data from different sensors to draw new conclusions. After analyzing data from different sensors, you create algorithms to recognize patterns. You use these algorithms to optimize your machine.

“We discovered an example during the development of our mobile IoT toilet. Despite the lack of a sensor to detect dirt, we were able to measure whether the toilet was clean or dirty. The combination of the door sensor and the occupied sensor allowed us to create algorithms. If the door is opened several times, but no one goes in, we can assume the toilet is dirty or defective,” added Leeggangers.

How to optimize your machine using sensor integration

Big data is indispensable when making your machine more intelligent. You determine what data you need based on customer requirements and your vision of the future. It is a challenge to collect this sensor data and then use algorithms to translate it into a machine optimization.

Moreover, you need the appropriate sensor solution to collect big data. Sensors will become increasingly intelligent in the future. What can we expect from these technologies?

Get to know what's going on. Learn the ins and outs of successful sensor technology implementation with our e-book.